Newsletter |

|

| Please register here |

Used and new machines

Process- and packaging machines

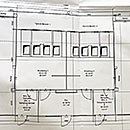

Cleanroom

| Producer | M+W Group |

| Type | |

| Year of construction | 2015 |

| Dimension ca. [in mm] | 17 x 9 x 2.5 m |

| Weight ca. [in kg] | 10000 |

| Country of origin | Germany |

| Link to the producer | www.mwgroup.net |

|

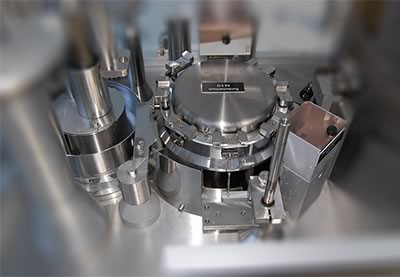

Machine Description Weighing cabin / sampling room for product and personal protection. GMP compliant clean room system with air circulation system. The areas MAL 1+2; MAL out; PAL and Musterzug 1+2 are pressurized via the central ventilation (e.g. monobloc). Additionally, recirculation filtering is active in the area of the two laminar flows (LF-23 and LF-25). For this purpose, the air is extracted close to the floor into the technical areas 1+2 and filtered down to HEPA 13 using a pre-filter. The air is then routed upwards and tempered via a heat exchanger. The air is then channeled into the two laminar flows, filtering to HEPA 14 using a final filter. In the original concept, the rooms outside the laminar flow were planned as ISO-8. According to the manufacturer, ISO5/6 would also be possible. The laminar flow area is generously dimensioned. This as-new unit is in EX version and includes the following components in mirror-inverted:

All rooms are controlled and monitored by Siemens technology (differential pressure monitoring, etc.). The cabin is constructed from a modular system. This makes it easy to customize the layout. |

|

Machine Categories

- Autoclaves/Oven

- Blister machines

- Cartoning machines

- Case packer

- Cleaning machines

- Closing machines

- Counting machines

- Feeding-systems

- Filling machines

- Filters / Laminar Flow

- Forklift trucks

- Handling-/Transportsystems

- Labelling machines

- Mills (Granulators etc.)

- Mixers

- Overwrappers / Banders

- Peripherie machines

- Printing machines

- Process machines

- Pumps

- Scales / check weigher

- Separators, Inspection machines

- Spare parts

- Tablet presses

- Various

- Vessel, Container, Tanks

▴